Developed highly active, high isotactic Ziegler-Natta

polymerization catalysts and Phthalate-free PP catalyst

Improved productivity with 3 times higher activity and

uniform morphology than commercial catalysts

Developed non-phthalate donor catalysts to respond

to strengthened phthalate compound regulations

Developed original technology of porous catalyst substrate

synthesis and commercially applied the same (2007)

Developed new catalyst using non-phthalate based

new internal donor and commercially succeeded in applying

the same (2014)

Won IR52 Jang Young-sil Award in the 38th week in 2007

Won IR52 Jang Young-sil Award in the 23rd week in 2014

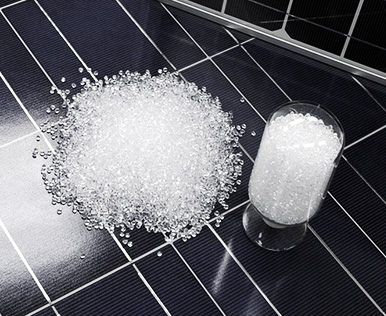

Ultra-high temperature / ultra-high pressure polymerization

initiator system and tubular reactor

Realized a uniform molecular structure and a clean

EVA material using the process polymerization technology

Improved solar cell efficiency and durability with

high transparency, zero defect and low shrinkage

Commercialized World's first tubular reactor process

Ranked 1st in global market share for solar cell encapsulments

Selected as a world-class product in 2015

Won IR52 Jang Young-sil Award in the 13th week in 2016

Developed HDPE material for bottle caps with

organoleptic high flow / ESCR characteristics

Demonstrated high rigidity, high flowability and high

ESCR characteristics simultaneously by tie molecule and

MWD control technology, and secured the world's highest

level of organoleptic properties.

Established No.1 supplier system in Asia

Led the market through quality differentiation

Selected as a world-class product in 2016

Developed high isotactic PP through catalyst with

wide molecular weight distribution and control of rubber

morphology

Improved thermal and mechanical properties due to

excellent isospecific property

Commercialize gas phase processes for the first time in

Korea using its own catalyst and polymerization process

technology (1995)

Long-term thermal stability UL IL Certification

Won IR52 Jang Young-sil Award in the 47th week in 1998

Flow mark free block PP for automobile bumpers and

ultra-high product with high flowability

Improved processability due to suppression of surface

flow mark and high flowability

Applied to the base composite materials for automobiles

at home and abroad

Won IR52 Jang Young-sil Award at the 2nd week of 2013

Predicted and translated SM (Styrene Monomer) catalyst

deactivation through computer simulation and improved

processes using the same

Developed the world's first Simulation-based Expert System

(SES) and new method of side-feeding SM, and applied

the same commercially

Increased SM process capacity by 10% (2013)

Developed simulator for simulation of ultra-high pressure

tubular LD / EVA polymerization process and prediction of

product properties

Secured 95% accuracy of temperature profile in a reactor

and 90% prediction accuracy of product property

Secured base technology by developing its own ultra-high

pressure polymerization process simulator

Improved process productivity, and developed

high value-added products

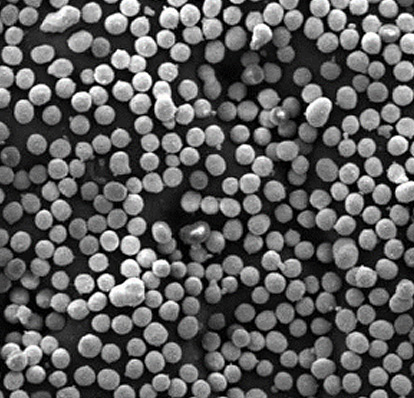

Ziegler-Natta catalyst for PP manufacturing with high-active,

high-hydrophobic and excellent covalent properties

More than twice the polymerization activity

compared to commercial catalysts

Increase productivity and process stability through uniform and

excellent catalytic shape control

Improved melt flowability and rubber content dramatically

through dough optimization

Development and commercial application of porous

catalyst manufacturing technology (2019)

Successful commercial production of new RTPO products with

high melting flow characteristics (2020)

Expanded application of high-value wire cable production

is underway

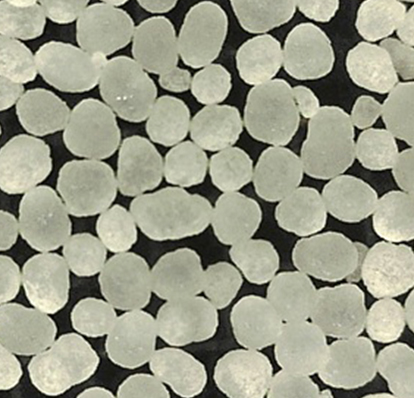

Ziegler-Natta polymerization catalyst for Very High

Molecular Weight PE production

3 times higher polymerization activity than commercial catalysts

Manufacture of Very High Molecular Weight PE with uniform

particle size and high apparent density

Development and commercial application of catalyst technology for

manufacturing Very High Molecular Weight PE (2019)

Successful commercial production of molecular weight between

250,000 and 2 million products (2020)

Entering and expanding the separation film market (2021~)

Eco-friendly products that can be recycled and energy-efficient as

materials used for insulators, which are the core of high-pressure

power cables.

PP manufacturing technology with excellent heat resistance,

softness, and voltage resistance

Eco-friendly PP for KEPCO’s 22.9 kV ground power distribution

Commercialization of power cables

Specialization and expansion of soft PP product lines

2020 New Technology Certification (NET)

High transparent, shock resistant, eco-friendly PP material

Application of proprietary catalysts and technologies

Won the IR52 Jang Young-sil Award for Week 6 2012

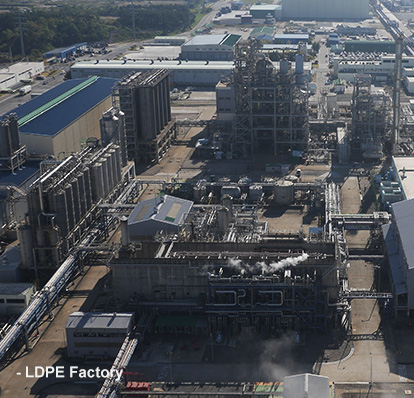

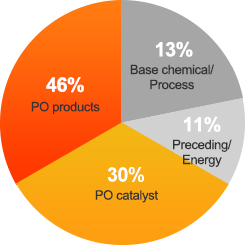

next-generation advanced materials and environment-friendly technologies through innovations in technology.

INTRODUCTION

Enhancing competitiveness of existing businesses, it is cultivating Seed technology for Hanwha TotalEnergies Petrochemical,

a 100-year-old company, through advanced core materials and eco-friendly technology research.

-

Chemical Company

Chemical Company

with CustomersHanwha TotalEnergies Petrochemical Research

Institute is leading new technology change

with customers from industrial basic materials

to next-generation advanced materials. Based

on understanding of the products customers

need, Hanwha TotalEnergies Petrochemical is raising

the future value of our customers through

innovations in technology. -

Chemical Company

Chemical Company

Capable of R&DHanwha TotalEnergies Petrochemical Research

Institute develops catalysts uniquely that play

a key role in determining the quality and

performance of products in the petrochemical

process, and stands comparison with

global technology leaders and has unique core

technologies in process technology and

materials technology. -

Satisfying Chemical Company

Satisfying Chemical Company

for ResearchersAs Hanwha TotalEnergies Petrochemical Research

Institute is located in the same place with a

plant, the product developed by researchers in

the lab can be commercialized directly in the

plant through scale-up process. In addition,

new materials and new process are comm

ercialized by constructing new plant, which

drums up enthusiasm for R&D among

researchers.

R&D FIELDS

-

Successfully developing and commercializing

Successfully developing and commercializing

a number of ultra-high performance catalyst

technologies, including Ziegler-Natta catalysts

for PE and PP, metallocene catalysts, and

next-generation eco-friendly catalysts,

Hanwha TotalEnergies Petrochemical is leading high-performance

polyolefin and innovations in manufacturing

technology.Major Research Fields

Ziegler-Natta PP,PE catalyst / Metallocene PP,PE catalyst -

Based on the research of the lab and pilot plant,

Based on the research of the lab and pilot plant,

Hanwha TotalEnergies Petrochemical is developing

high value-added basic petrochemicals,

derivatives, polymer products and processes; and

developed product properties of process architecture and

yield prediction models, based on computer simulation,

to improve process efficiency, develop new products, and

study optimization of the entire plant.Major Research Fields

Computer simulation / Process optimization and

product property prediction model

/ Research on new product, scale-up catalyst

/ Development of new process

-

Hanwha TotalEnergies Petrochemical is developing differentiated

Hanwha TotalEnergies Petrochemical is developing differentiated

products that meet customer needs in various fields,

such as automobiles, home appliances, films, caps, solar power,

etc. through study of high performance of PP, PE, and PP compounds.Major Research Fields

High rigidity·high heat resistant material / Low odor material

High purity·high transparency material / High-gloss·lightweight material -

Hanwha TotalEnergies Petrochemical is engaged in various R&D fields:

Hanwha TotalEnergies Petrochemical is engaged in various R&D fields:

crude oil / condensate evaluation and optimal utilization technology,

which is the core material of the company; design of

high-performance clean fuel oil product and development of

production technology; maximization of basic petrochemical value;

optimal utilization of by-products, and improvement of production.Major Research Fields

Diversification of raw material

/ Improvement and development of catalysts

/ Design of optimal product

-

Developing core technologies, such as polymer

Developing core technologies, such as polymer

polymerization technology, polymer structure

control technology, nanomaterial synthesis technology,

and surface property control technology,

Hanwha TotalEnergies Petrochemical secures technologies

needed to start new business and develops products for

future growth of the company.Major Research Fields

Eco-friendly material / Specialty material / C4,C5 material

RESEARCH ACHIEVEMENT

abroad like Jang Young-sil Award, domestic technology certification, and the selection of 100 technology of the 20th century.

Excellent Corporate Research Institute (2000)

IR52 Jang Young-sil Award : 14 times New Excellent Technology Certification : 15 times Korea's Top 100 Technologies of the 20th Century : 2 cases

Top 10 New Technology Awards (2000)

Grand Prize in the Precision Technology

Promotion Competition (2000)

1998 Ultra-high heat resistant, high rigidity polypropylene

1999 Next-generation HDPE new material with

ultra-high rigidity, ultra-high toughness

2001 Ultra-high strength C6 copolymer new material

Ultra-high flow, ultra-high impact RTPO

2005 High melt tension polypropylene

2007 Ultra-high active PP new catalyst

2009 Non-coated high-gloss scratch resistant polypropylene

2010 PP / clay nanocomposite side seal molding

Metallocene PE new material with improved

transparency, gloss and processabilty

2012 Clear / ultra-high impact polypropylene

2013 Interior and exterior parts for automobiles with PP

compounds with high quality surface characteristics

2014 Next-generation, eco-friendly Phthalate free PP catalyst

2016 Highly transparent EVA new material

2018 Paintless injection crash pa

| Category | Domestic | Overseas | Total |

|---|---|---|---|

| Application | 72 | 87 | 159 |

| Registration | 448 | 265 | 713 |

| Total | 520 | 352 | 872 |

-

Polymerization Catalyst

for PP Production VIEW MORE - EVA for Solar Cell Materials VIEW MORE

- HDPE for Bottle Caps VIEW MORE

- High Isospecific PP(HIPP) VIEW MORE

- PP for High-gloss Automobiles VIEW MORE

-

Development of New Process

of SM through Simulation VIEW MORE -

LD / EVA Polymerization

Reaction Simulator VIEW MORE -

Shock resistant RTPO

catalyst VIEW MORE -

Catalyst for Very High Molecular

Weight Poly-Ethylene(PE) VIEW MORE -

PP for eco-friendly

power cables VIEW MORE -

CLEAR SUPER-IMPACT

Material VIEW MORE