Polymer

Hanwha TotalEnergies Petrochemical produces typical plastic raw materials which are widely used in everyday life,

such as automobiles, household appliances, packaging materials and household goods.

INTRODUCTION

Polymer is an indispensable product in our daily lives that is used as a raw material and intermediate product of various industries.

Typical synthetic resin product is called 'rice of the industry' because it is in the form of pellets similar to a grain of rice.

As for polymer business of Hanwha TotalEnergies Petrochemical, naphtha is cracked at the naphtha cracking center (NCC)

to produce basic petroleum like ethylene of 1.53 million tons and propylene of 1.00 million tons per year,

which in turn are used as raw materials for synthetic resin products such as HDPE, LDPE, LLDPE, EVA, PP, and composite PP.

BUSINESS STATUS

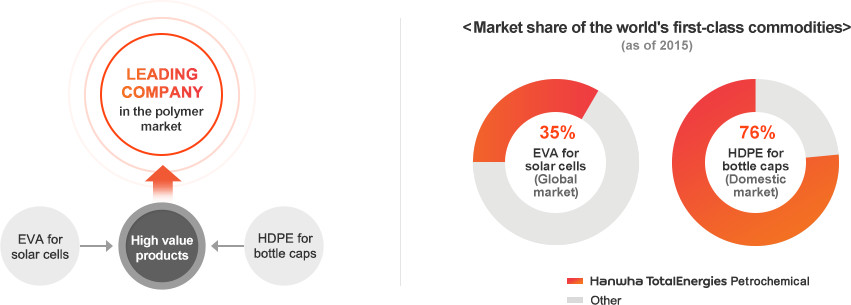

Hanwha TotalEnergies Petrochemical is playing a leading role in polymer markets in Asia, reorganizing portfolios focusing on high value-added

products that meet customer needs away from conventional products. As a result, Hanwha TotalEnergies Petrochemical's EVA for solar batteries,

HDPE for bottle caps and FMF PP were selected as world-class products, respectively, and were recognized for our superior product competitiveness.

competitiveness. Hanwha TotalEnergies Petrochemical expanded its No.2 EVA plant in 2014, raising EVA's annual output to 320 thousand tons, and

laying the foundations to preoccupy the EVA market. Hanwha TotalEnergies Petrochemical plans to lead the global high-value polymer market by

increasing the production of basic raw materials through expansion of NCC, expanding the market share of TERPOLYMER PP, and expanding ADL

(Advanced Double Loop) plant to increase production of high value-added PE products.

PRODUCTS

Find out about different types of Polymer.

-

High Gloss PP CompoundHaving excellent gloss and heat resistance, it has physical properties suitable for electrothermal products and food related products. It has higher rigidity and dimensional stability than conventional PP along with excellent long-term thermal stability.

ex) Exterior materials for small electrical and electronic products, such as coffee makers, irons, electric rice cookers -

Weatherability PP CompoundIt has excellent moldability by using Base PP which has high melt flow index. As it has excellent light resistance and weatherability, and is less discolored against UV, it is used for outdoor products such as high temperature lighting equipment and outdoor unit of air conditioner.

ex) Lighting parts, insulating plate, electric plug, outdoor unit of air conditioner -

Anti-Fungus PP CompoundIt is a product with outstanding balance of rigidity and impact strength as well as anti-fungus property. Especially, with its good fluidity, it has excellent moldability, and its excellent heat discoloration resistance and light resistance are good for hygienic products requiring anti-fungus property. Hanwha TotalEnergies Petrochemical PP compound is an excellent product that has passed the antibacterial test conducted by external testing laboratory.

ex) caps for PET bottles, food containers, plastic boxes, packaging films for industrial use, pallets, and pipes -

High Impact PP CompoundEquipped with high impact strength, good moldability and weatherability, it is used for exterior materials such as automobile bumpers and in-panels. Hanwha TotalEnergies Petrochemicalh-impact PP compounds of various grades that meet the needs of customers.

ex) Exterior materials such as automobile bumpers -

High Rigidity PP CompoundIt is a product whose mechanical rigidity and heat resistance were upgraded by combining and reinforcing general PP with glass fiber. It has excellent quality using various base PPs such as HIPP (High Isotactic Polypropylene) and excellent processing technology of Hanwha TotalEnergies Petrochemical ex) Air conditioners, washing machines

-

Flame Retardant PP CompoundIt is a product with distinct characteristics to prevent fire from continuing burning by extinguishing the flame, in the event of fire. Depending on the application, properties such as high rigidity and weatherability may be added. It is used for parts such as lighting, TV, and motor peripheral that are highly likely to ignite due to heat generation.

ex) Lighting parts, TVs, refrigerators, vacuum cleaners -

Heat Resistant PolypropyleneIt is a product whose rigidity and heat resistance were greatly improved compared to general PP by adding talc which is inorganic filler to general PP. As Hanwha TotalEnergies Petrochemicalant PP compound has excellent long-term heat resistance, heat discoloration resistance and dimensional stability as well as excellent rigidity, it can be used in electric and electronic parts under high temperature environment. In addition, it has excellent quality by using various base PPs such as HIPP (High Isotactic Polypropylene) and excellent processing technology of Hanwha TotalEnergies Petrochemical ex) Electric and electronic products, such as coffee makers, electric rice cookers, air conditioners, dishwashers, interior and exterior materials for automobiles

-

HOMO PP

HOMO PolypropyleneIt is composed of single bonds of propylene only. It has high crystallinity and relatively good mechanical properties such as tensile strength and rigidity, and is used for general purpose applications such as household appliances and industrial parts.

ex) Household appliances and industrial parts -

BLOCK PP

BLOCK PolypropyleneIt is an upgraded product of the low temperature impact properties of homo PP, which is made by copolymerizing propylene and ethylene. It is composed of homo PP and block of ethylene-propylene copolymer and is used in industrial parts requiring high impact strength such as automobiles, and electric and electronic products.

ex) Automobiles and electric and electronic products -

RANDOM PP

RANDOM PolypropyleneIt is an upgraded product of transparency and flexibility of Homo PP, which is made by copolymerizing propylene and ethylene and arranging two monomers randomly. It is used for products requiring transparency and flexibility, such as household appliances, food · clothing packaging.

ex) Household appliances and food · clothing packaging -

TER PP

Terpolymer PolypropyleneIt is a product produced by using ethylene and 1-butene as a co-monomer in addition to propylene. It has better physical properties in terms of transparency compared to Homo PP, and has a low melting point, so it is used as a raw material for products requiring low temperature processing; It is used in thermal adhesive films such as films for packing foods, beverages and so on.

ex) Thermal adhesive films for foods, and beverages

-

LDPE

Low Density PolyethyleneLow density polyethylene (LDPE) is a synthetic resin produced by polymerizing ethylene, which is a typical synthetic resin product used in everyday life. It has excellent processability, flexibility and transparency among synthetic resin products and is used as a raw material for agricultural and packaging transparent film, cable coating, and disposable product.

ex) Transparent film for agricultural and packaging, cable coating, and disposable product -

EVA

Ethylene Vinyl AcetateIt is a typical synthetic resin product produced by copolymerizing ethylene and vinyl acetate. Its density and flexibility increase depending on the content of vinyl acetate. It is used for various applications such as foam molding products such as sneaker outsole and film adhesive. Hanwha TotalEnergies Petrochemical's EVA for solar batteries, a high value-added product, was selected as a world-class product in 2015 and recognized for its technology.

ex) Encapsulants for solar batteries, Extrusion coating, Sneaker midsole -

LLDPE

Linear Low Density PolyethyleneLLDPE has similar feature to LDPE, but it is more specialized in manufacturing film with good intensity.

ex) Film product -

HDPE

High Density PolyethyleneHigh density polyethylene (HDPE) is a synthetic resin produced by polymerizing ethylene, which is a typical synthetic resin product used in everyday life. With its impact and cold resistance, it is widely used in various containers and plastic boxes. Hanwha TotalEnergies Petrochemical's HDPE products are produced in a state-of-theart manufacturing process with low pressure polymerization and are recognized worldwide for their excellent processability and quality.

ex) Caps for PET bottles, food containers, plastic box es, packaging films for industrial use,pallets, and pipes